What is EPS?

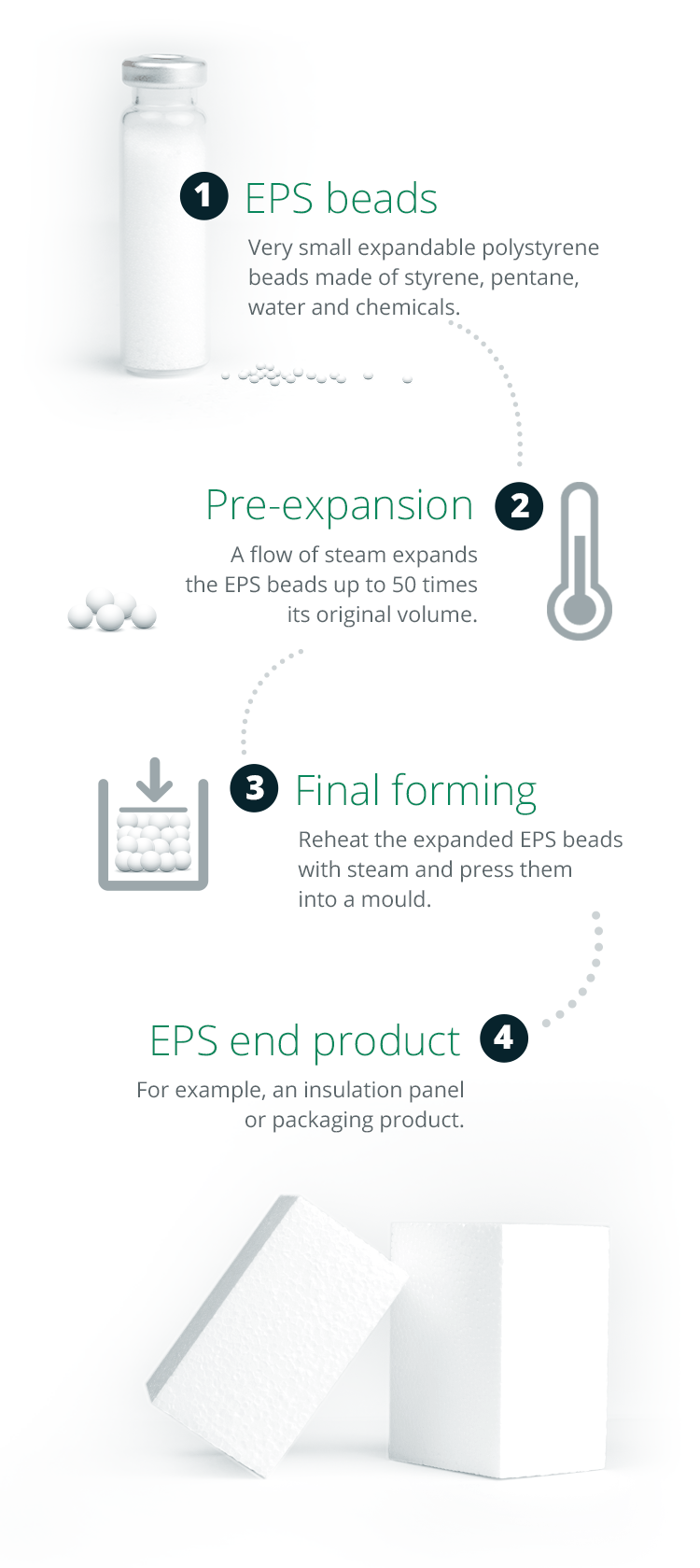

Expandable Polystyrene (EPS) is a polymer with a number of unique properties.

EPS consists of 98% air, has an excellent insulation value, is light yet rigid. Unlike other insulation materials, EPS also has minimal water absorption.

♻️ 100% Recyclable

Additionally, EPS allows for easy and safe processing, is sustainable and 100% recyclable. In this way, EPS makes an excellent contribution to further reducing CO₂ emissions.

Areas of application

The unique properties referred to above have over several decades made EPS a highly successful raw material that can be used in a broad range of products and applications. Examples include applications in the building and construction industry, packaging industry, agriculture and civil engineering sectors.